Brake lines are an integral part of a vehicle’s braking system. These lines are responsible for transferring hydraulic pressure from the master cylinder to the brake components, allowing for effective braking. They are typically made of steel or other durable materials with high resistance to corrosion and pressure. Brake line need to be securely fastened and properly routed to avoid any damage or failure. Regular inspection and maintenance are essential to ensure the integrity and functionality of brake lines.

Understanding

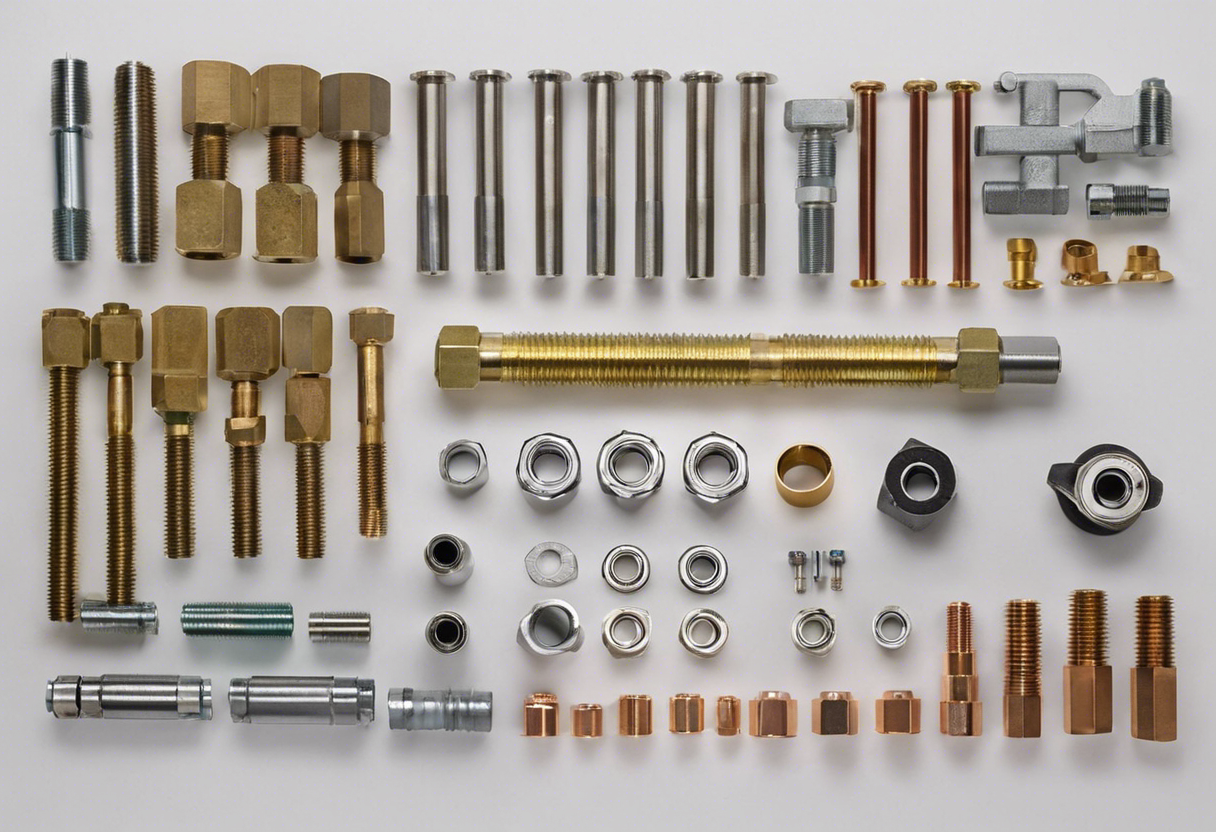

- Fittings: Fittings are the connectors that join brake lines to various brake components, such as calipers, wheel cylinders, and the master cylinder. They ensure a secure and leak-proof connection between the brake line and the components they serve. Fittings come in various types, such as flare fittings, compression fittings, and banjo fittings. Choosing the correct fitting type is crucial to ensure compatibility and proper functioning of the brake system.

- Types of Brake Lines: There are primarily three types of brake line used in vehicles: steel, rubber, and nylon. Steel lines are the most common and are highly durable, providing excellent resistance to pressure and corrosion. Rubber lines are flexible and allow for easy installation, but they are less durable and may deteriorate over time. Nylon lines are lightweight, flexible, and corrosion-resistant, making them a popular choice for modern vehicles.

- Brake Line Sizes: Brake line come in different sizes, typically measured in inches or millimeters. The size of the brake line is determined by the diameter of the tubing used. Common sizes include 3/16″, 1/4″, and 3/8″. It is crucial to use the correct size brake line for optimal brake performance and safety. Consult the vehicle’s manual or seek professional advice to determine the appropriate size for your specific vehicle.

Types of Brake Lines

There are several types of brake lines available, each with its own unique characteristics and advantages. Here are some of the most common types:

- Steel Brake Lines: Steel brake line are the most widely used type of brake line due to their durability and strength. They are made from seamless steel tubing, which resists corrosion and can withstand high pressure. Steel brake line are often used in heavy-duty vehicles and are known for their reliability.

- Braided Stainless Steel Brakes: Braided stainless steel brake lines offer increased flexibility and resistance to wear. They are constructed by covering a steel braid with a protective outer layer, usually made of rubber or Teflon. These lines provide improved brake pedal feel and responsiveness, making them popular among performance enthusiasts.

- Rubber Brake Line: Rubber brake line are cost-effective and commonly used in most standard vehicles. They are made from EPDM (ethylene propylene diene monomer) rubber, which offers good heat resistance and flexibility. However, rubber brake lines are more prone to deterioration over time, making regular inspection and maintenance essential.

When choosing a brake line, factors such as vehicle type, driving conditions, and personal preferences should be taken into account. It is crucial to select a brake line that meets the specific requirements of your vehicle to ensure optimal performance and safety.

Choosing the Right Brake Line Material

When it comes to choosing the right brake line material, there are a few options to consider. Each material has its own set of advantages and disadvantages, so it’s important to choose one that best suits your specific needs and preferences. Here are some factors to consider when making your decision:

- Steel: Steel brake line are one of the most common choices due to their durability and strength. They are resistant to corrosion and can withstand high pressure, making them suitable for heavy-duty applications. Steel lines are also relatively inexpensive, making them a cost-effective option.

- Stainless Steel: Stainless steel brake line offer similar benefits as steel lines but with the added advantage of better corrosion resistance. Stainless steel lines also have a sleek appearance, making them a popular choice for car enthusiasts.

Brake Line Maintenance and Inspection

To ensure the proper functioning of brake lines, regular maintenance and inspection are essential. Here are some key points to consider:

- Visual inspection: Start by visually inspecting the entire length of the brake lines. Look for any signs of damage such as cracks, abrasions, bulges, or corrosion. Pay close attention to the areas near fittings and connections, as they are prone to leaks.

- Brake fluid leakage check: Brake fluid leakage compromises the effectiveness of the braking system. Inspect the brake lines for any signs of fluid leaks. Look for wet spots, drips, or a decrease in brake fluid levels.

- Bend and kink inspection: Ensure that the brake lines are free from any sharp bends or kinks, as these can restrict the flow of brake fluid and affect braking performance.

- Fitting inspection: Examine the fittings and connections for any signs of looseness or damage. Tighten any loose fittings and replace any damaged ones promptly.

- Brake line flush: Over time, brake fluid can become contaminated with moisture and debris, which can result in brake system failure. Regularly flush the brake lines and replace the brake fluid according to the manufacturer’s guidelines.

- Rust prevention: Brake lines are prone to rust, especially in areas with harsh weather conditions. Apply a rust inhibitor or coating to protect the brake lines from corrosion.

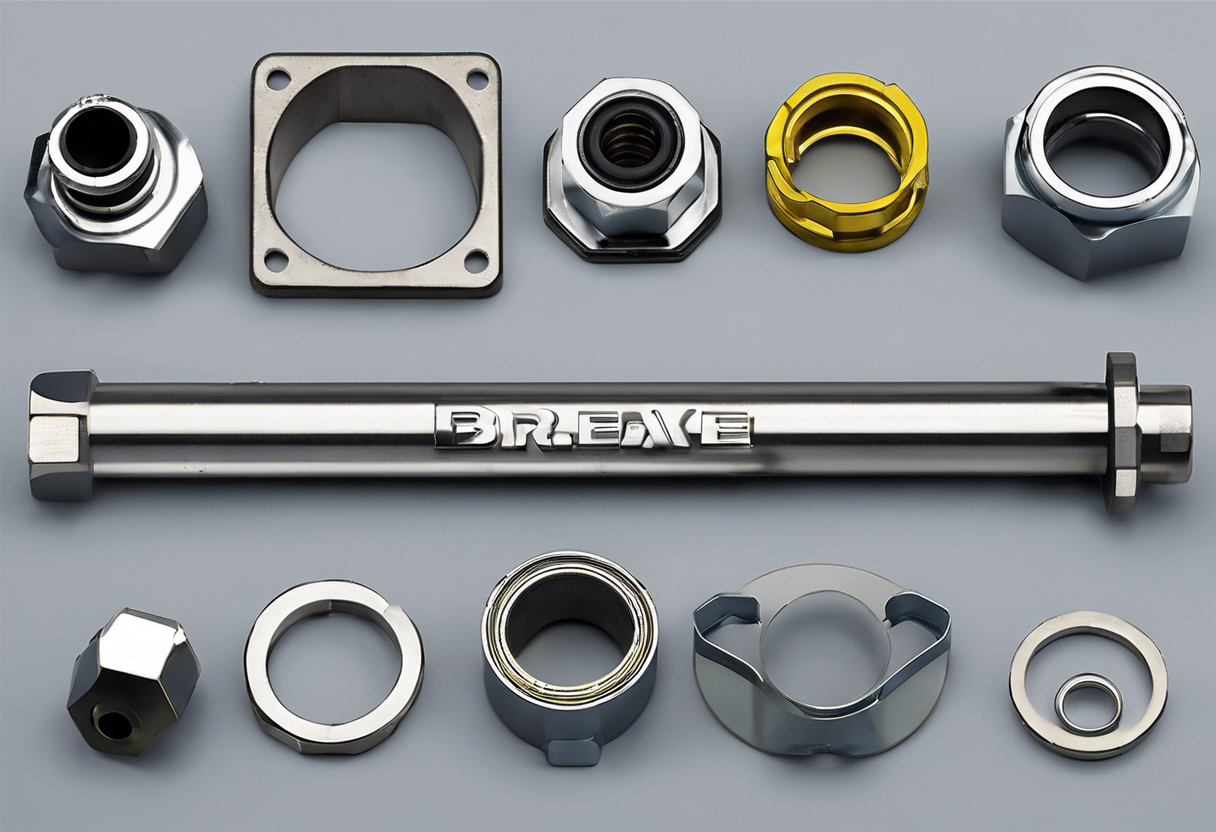

5. Upgrading Brake Lines and Fittings

Upgrading brake lines and fittings is a step that many car enthusiasts take to enhance their braking system’s performance and safety. High-quality brake lines and fittings can improve brake pedal feel, increase braking power, and improve overall brake performance.

When upgrading brakes, it is important to choose lines made from durable materials such as stainless steel or Teflon. These materials offer superior strength and resistance to corrosion, preventing leaks and ensuring a longer lifespan for the brake line. Upgraded brakes also have a higher tolerance for extreme temperatures, making them suitable for high-performance driving.

In addition to the brake line themselves, upgrading fittings is equally important. Fittings ensure proper connection and secure transmission of brake fluid through the brake system. Upgrading to high-quality fittings helps prevent leaks and maintain consistent brake pressure, which is crucial for efficient stopping power.

It is recommended to upgrade brake lines and fittings as a complete kit to ensure compatibility and ease of installation. These kits usually come with all the necessary hardware, including banjo bolts, washers, and mounting brackets. Following the manufacturer’s instructions is essential for proper installation and to avoid any issues that may compromise brake performance.

Taking the time to upgrade brake lines and fittings is a worthwhile investment for any car owner looking to improve their vehicle’s braking performance. It not only enhances safety but also provides a more responsive and reliable braking experience, making it a valuable upgrade for both daily driving and high-performance applications.

Common Brake Line Issues and Solutions

- Corrosion: One of the most common brake line issues is corrosion. Over time, brake lines can deteriorate due to exposure to moisture, salt, and other corrosive substances. This can result in weakened or damaged brakes , leading to reduced braking performance. The solution to this problem is to regularly inspect and replace corroded brakes. Using corrosion-resistant materials, such as stainless steel or copper-nickel alloy, can also help prevent future corrosion.

- Leaking Brake Fluid: A leak in the brake line can cause a loss of brake fluid, resulting in reduced braking power. Common causes of brake fluid leaks include damaged or worn-out fittings, loose connections, or faulty seals. To solve this issue, it is important to identify the source of the leak and repair or replace the affected parts. Regularly checking brake fluid levels and addressing any leaks promptly can prevent safety hazards and ensure optimal brake performance.

- Frayed or Damaged Brake Lines: Brake line can become frayed or damaged due to external factors like road debris or internal wear and tear. These damaged lines can compromise brake function and lead to brake failure. In such cases, the affected brake lines should be replaced with new ones. It is also essential to secure the brake lines properly and protect them from potential damage to ensure their longevity and functionality.

By understanding these common brake line issues and their solutions, vehicle owners and technicians can ensure the safety and reliability of the braking system. Regular maintenance, inspection, and timely repair or replacement of brake line are essential for optimal brake performance and overall vehicle safety.

Installing or Replacing Brake Lines

When it comes to installing or replacing brake line, it is important to follow the proper procedure to ensure the safety and effectiveness of the braking system. Here are the steps to guide you through the process:

- Gather the necessary tools: Before starting the installation or replacement, make sure you have all the required tools at hand. This may include a flare nut wrench, line wrench, tubing bender, tubing cutter, and brake line flare tool.

- Lift the vehicle: If you’re replacing the brake line, you’ll need to lift the vehicle using a jack and jack stands to access the damaged lines. Make sure the vehicle is securely supported before proceeding.

- Remove the old brakes: Use the appropriate wrenches or line wrenches to loosen and remove the fittings from both ends of the brake line. Carefully remove the old brake line, taking note of their routing and any specific clips or brackets they may be attached to.

- Measure and cut the new brakes: Using a tubing cutter, measure and cut the new brake lines to the required length. It’s important to ensure accurate measurements to avoid any interference or incorrect installation.

- Bend the brakes: Using a tubing bender, carefully bend the new brake lines to match the shape and routing of the old lines. Take your time to ensure smooth and precise bends that allow for proper installation and clearance.

- Install the new brake lines: Begin by attaching the fittings to the new brakes, making sure they are tight and secure. Follow the original routing and use any clips or brackets as necessary to secure the lines in place.

Tips for DIY Brake Line Replacement

When it comes to replacing brakes on your own, there are a few important tips to keep in mind. Taking the proper precautions and following the correct procedures will ensure a successful and safe replacement. Here are some tips to consider:

- Safety First: Always prioritize safety when working on your vehicle’s brake system. Make sure to wear protective goggles and gloves to prevent any injury.

- Gather the Right Tools: Before you start, gather all the necessary tools and materials for the job. This may include a tubing cutter, flare wrenches, brake line fittings, and brake fluid.

- Inspect the Lines: Before removing the old brake line, thoroughly inspect them for any signs of damage or corrosion. If you notice any issues, it’s best to replace the entire line.

- Follow a Systematic Approach: It’s essential to work in a systematic manner when replacing brake line. Start by removing the old lines, one section at a time, and carefully route the new lines along the same path.

- Proper Flaring: When making new brake line connections, ensure that you properly flare the ends using a flaring tool. This will create a tight and reliable seal.

Remember, if you’re not confident in your ability to replace brake lines yourself, it’s always best to leave the job to a professional.

Conclusion

In conclusion, brake lines and fittings are crucial components of a vehicle’s braking system. They play a vital role in delivering hydraulic pressure to the braking system, ensuring effective stopping power. It is important to choose the right type of brake line and fittings that are compatible with your vehicle’s specifications.

When selecting brake , consider factors like material, size, and flexibility. Stainless steel brake line are a popular choice due to their durability and resistance to corrosion. Ensure that the brake meet the required specifications for your vehicle.

When it comes to fittings, it is essential to use fittings specifically designed for brake systems to ensure proper connectivity and a secure seal. Always follow the manufacturer’s recommendations and guidelines when installing or replacing brake line and fittings.

Regular inspection and maintenance of brake and fittings are necessary to ensure their optimal performance and safety. Check for any signs of wear, damage, or leaks, and replace them if necessary. Regularly flushing and bleeding the brake system can also help maintain its efficiency.

Remember to consult a professional mechanic or refer to the vehicle’s manual for any specific maintenance procedures or recommendations.

By understanding the different types of brake line and fittings and their importance, you can make informed decisions when it comes to maintaining and upgrading your vehicle’s braking system. Prioritizing the safety of your vehicle and its occupants should always be a top priority, and the proper maintenance of brake line and fittings is an essential aspect of that.

FAQs About Brake Line

Read More: https://www.youtube.com/watch?v=lEH8iEd9Zc8

Read More: https://manualwheel.com/common-problems-…s-oil-stabilizer/