Selecting the correct AN fittings for your plumbing system is crucial for ensuring optimal performance and functionality. AN fitting, also known as Army Navy fittings, are designed to create a secure connection between hoses or pipes in various applications, including automotive, industrial, and marine systems. These fittings feature a standardized thread size and a flare on the end to provide a leak-proof seal.

When choosing AN fitting, it is important to consider factors such as the type of fluid being transported, the pressure and temperature requirements, and the compatibility with other components in the system. The right AN fitting will ensure a tight, reliable connection that can withstand the demands of your plumbing system.

In this article, we will explore the key considerations to keep in mind when selecting AN fitting for your plumbing system. We will discuss the different types of AN fittings available, the materials they are made from, and the importance of proper sizing and installation. By understanding these factors, you will be able to make an informed decision and choose the right AN fitting for your specific application.

The History and Evolution of AN Fittings

AN fittings, short for Army/Navy fittings, have a rich history and have evolved significantly over time. The aerospace industry required fittings that could withstand high fluid pressures and ensure a secure connection to prevent leaks in critical systems.

Over the years, AN fitting have undergone several changes and improvements. One significant development was the adoption of a standardized sizing system. AN sizes are denoted by a number which corresponds to the outer diameter of the tubing. This standardized system has made it easier for users to select the right fittings for their specific applications.

Another evolution in AN fitting has been the introduction of different materials to better suit various needs. Initially, AN fitting were made from aluminum, making them lightweight and corrosion-resistant. However, as applications expanded, different materials such as stainless steel and brass became available. These materials offer enhanced durability and resistance to high temperatures.

In recent years, there has also been a surge in the availability of AN fitting with improved sealing mechanisms. Traditional AN fitting used a flare and a cone-shaped fitting to create a seal. However, advancements have led to the development of O-ring seal fittings as well as push-lock fittings, which simplify installation and offer improved sealing capabilities.

The evolution of AN fitting has allowed for greater flexibility and reliability in plumbing systems across industries. With standardized sizing, a variety of material options, and improved sealing mechanisms, users can now select AN fitting that best meet their specific requirements.

In conclusion, the history and evolution of AN fitting reflect the demands of various industries for reliable and high-performance plumbing components. From their origins in military and aerospace applications to their widespread use today, AN fitting have undergone significant improvements to provide secure connections and withstand demanding conditions.

Understanding the Terminology and Sizing of AN Fittings

AN fittings, also known as Army-Navy fittings, are commonly used in high-performance automotive and industrial plumbing systems. To ensure proper installation and compatibility, it is essential to understand the terminology and sizing of these fittings.

- AN Size: They are sized using a numeric system that corresponds to the tubing or hose diameter. The AN sizing ranges from -2 to -32, with each number representing a specific tubing diameter in 1/16th of an inch increments. For example, AN-6 fitting corresponds to a 6/16 inch or 3/8 inch tubing.

- Thread Sizes: They require precise thread sizes to ensure a secure and leak-free connection. The most common thread size for AN fitting is 37 degrees, known as AN/JIC (Joint Industry Council) threading. However, other threading standards like NPT (National Pipe Thread) may also be used in certain applications.

- Flare Type: They utilize a flare-type connection, where the tubing end is flared to create a mating surface. The nut of the fitting compresses and seals this flare against the fitting body, ensuring a tight connection. They typically feature a 37-degree flare angle, referred to as the “JIC” flare.

Understanding AN fitting terminology and sizing is essential for selecting the right fittings for your plumbing system. Ensure accurate measurements, precise threading, and compatible materials to achieve reliable and efficient connections.

Pros and Cons of AN Fittings

They are widely used in plumbing systems, providing several benefits that contribute to their popularity. However, it is important to consider the drawbacks as well. Here are the pros and cons of AN fitting:

Pros

- Leak-free connections: AN fitting are known for their superior sealing capabilities. The flare design and the use of O-rings ensure tight connections, minimizing the risk of leaks. This is especially crucial in high-pressure applications, where even a small leak can have significant consequences.

- Wide compatibility: They are designed to be compatible with various fluids, including oil, fuel, coolant, and hydraulic fluids. This versatility makes them suitable for a wide range of automotive, industrial, and racing applications.

- Flexible installation: They offer flexibility in installation due to their modular design. They can be easily disassembled and reassembled, allowing for modifications or repairs without the need for specialized tools or equipment.

- Durable construction: They are commonly made from materials like aluminum or stainless steel, which are known for their durability and resistance to corrosion. This ensures their longevity and reliability in demanding environments.

Cons

- Cost: They tend to be more expensive compared to traditional threaded fittings. The higher cost is often justified by their superior performance and durability, but it should be taken into consideration when budgeting for a plumbing system.

- Specialized knowledge and tools: They require specific knowledge and tools for proper installation. The flaring process, for example, demands precision and expertise to ensure a secure connection. This may require additional training or the assistance of a professional.

Careful consideration of these pros and cons will help make an informed decision when choosing Them for your plumbing system. Different types of AN fittings and their applications

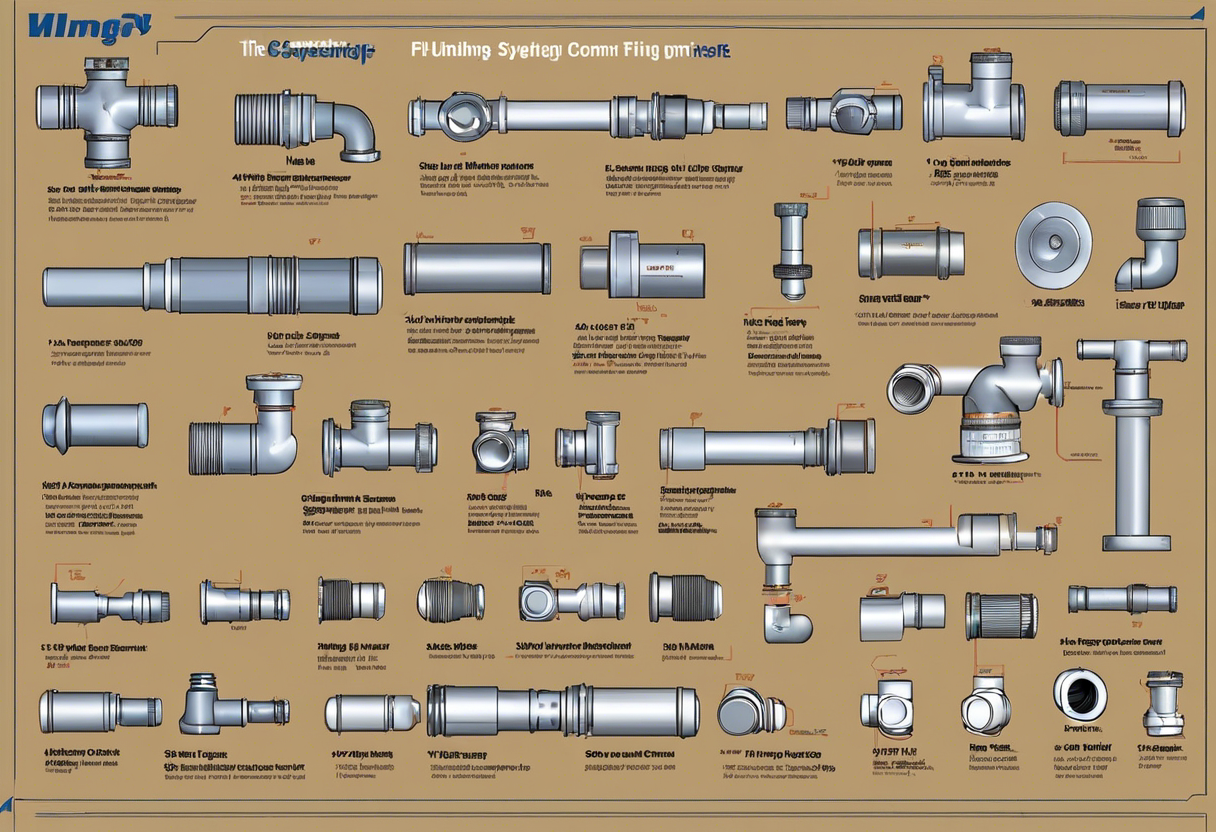

They , also known as Army-Navy fittings, are used in various plumbing systems, including automotive and industrial applications. These fittings utilize a 37-degree flared cone design to ensure a reliable and leak-free connection. Here are some different types of AN fittings and their specific applications:

- AN Hose Ends: AN hose ends are used to connect the hose to other AN fitting or components. Available in various sizes, they provide a secure connection and allow for easy assembly and disassembly of hoses. These fittings are commonly used in fuel systems, oil coolers, and hydraulic systems.

- AN Adapters: AN adapters are used to connect different sizes or types of Them. They act as a bridge between two fittings with different thread sizes or configurations. These adapters are widely used in custom plumbing setups and allow for flexibility in system design.

Choosing the Right AN Fittings for Your Project

When it comes to your plumbing system, selecting the appropriate AN fitting is crucial for a successful project. AN fitting, also known as Army-Navy fittings, are a type of standardized fitting used in various industries such as automotive, aerospace, and racing.

Here are some factors to consider when choosing the right AN fitting:

- Size: come in various sizes, typically designated by a number, such as AN-4, AN-6, AN-8, and so on. It is essential to determine the size of your plumbing system and select fittings that match the required size.

- Type: They come in different types, each serving a specific purpose. A few common types include straight fittings, elbow fittings, tee fittings, and bulkhead fittings. Understanding the layout and requirements of your plumbing system will help you determine the appropriate type of AN fittings to use.

- Sealing Method: They can use different sealing methods, such as O-ring seals or sealing tape. Consider the specific needs of your project and select fittings that offer a secure and reliable sealing method.

- Compatibility: Ensure compatibility between your AN fitting and other components of your plumbing system, such as hoses and adapters. Using incompatible fittings can result in leaks, reduced performance, or damage to the entire system.

In conclusion, choosing the right AN fitting for your plumbing system is essential for its overall functionality and reliability. By considering factors such as size, material, type, pressure rating, sealing method, and compatibility, you can ensure a well-designed and efficient plumbing system for your project.

Installing and maintaining AN fittings

When it comes to installing and maintaining AN fitting, there are a few key steps to follow to ensure a proper and leak-free connection. Here are some guidelines to help you get started:

- Preparation: Before installing AN fitting, make sure to clean and inspect the surfaces where the fittings will be installed. Remove any dirt, debris, or old sealing material to ensure a secure fit.

- Proper torque: One of the most important aspects of installing AN fitting is applying the correct amount of torque. Use a torque wrench to tighten the fittings to the manufacturer’s specifications. Over-tightening can damage the fitting, while under-tightening can lead to leaks.

- Sealing: They typically require a sealing compound or tape to create a leak-free connection. Apply the proper sealing material to the threads of both the fitting and the component it will be attached to. Be careful not to overapply, as excess sealing material can hinder the proper tightening of the fitting.

- Inspection: After installation, inspect the fittings for any signs of leaks. It’s important to catch any potential issues early on to prevent damage to your plumbing system. If you notice any leaks, try tightening the fitting slightly. If the leak persists, it may be necessary to disassemble, clean, and reassemble the fitting with new sealing material.

- Regular maintenance: To ensure the longevity and performance of your AN fitting, regular maintenance is essential. Inspect fittings periodically for signs of wear, corrosion, or damage. Replace any fittings that show signs of deterioration to prevent leaks or failure.

By following these steps and paying attention to proper installation and maintenance techniques, you can enjoy a reliable and leak-free plumbing system with AN fitting. Remember to always consult the manufacturer’s instructions and guidelines for specific fittings and applications.

Troubleshooting common issues with AN fittings

When working with AN fitting in your plumbing system, it is essential to be aware of potential problems that may arise. Here are some common issues you may encounter and troubleshooting tips to help you resolve them:

- Leakage: One of the most common issues with AN fittings is leakage. This can occur due to improper installation or damaged fittings. To troubleshoot and fix leakage, tighten the fittings adequately using the correct tools. It is also essential to inspect the fittings for any signs of damage or wear and replace them if necessary.

- Cross-threading: Another common problem is cross-threading, which happens when the threads of the fitting and the component do not align properly. This can lead to stripped threads and unsafe connections. Apply gentle pressure, ensuring the threads engage smoothly.

- Over-tightening: Over-tightening AN fitting can result in damaged threads, making it difficult to remove or replace the fitting. It is crucial to use the appropriate torque specifications provided by the manufacturer. Always refer to the recommended torque values and use a torque wrench for accurate tightening.

- Incompatibility: They come in various sizes and styles, and using incompatible fittings can cause problems. Ensure that you select fittings that are compatible with your plumbing system and the components you are connecting. Double-check the size, thread type, and fitting style to avoid any compatibility issues.

Remember to always follow manufacturer guidelines and recommended practices when troubleshooting AN fittings. Taking the time to address and resolve these common issues will help ensure the longevity and performance of your plumbing system.

Conclusion and Final Thoughts

In conclusion, selecting the right AN fitting for your plumbing system is a critical aspect of ensuring a leak-free and efficient operation. By understanding the different types and sizes of AN fitting, as well as their compatibility with various plumbing components, you can make an informed decision that meets your specific needs.

When choosing AN fitting, consider factors such as material compatibility, pressure rating, and size requirements. Stainless steel AN fitting are often preferred for their durability and resistance to corrosion. Brass AN fitting, on the other hand, can be more cost-effective but may not offer the same level of longevity.

Remember to measure and determine the correct AN size for your plumbing system. The AN numbering system, while initially confusing, becomes more familiar with practice. Ensure that your fittings and adapters are compatible in terms of thread size and gender.

Regular inspection and maintenance of AN fitting are essential to identify any signs of wear or damage. It is crucial to replace any worn-out or damaged fittings promptly to prevent potential leaks and system failures.

In conclusion, selecting the right AN fitting requires careful consideration of various factors such as material, size, and compatibility. By following these guidelines and understanding the specific requirements of your plumbing system, you can confidently choose AN fitting that optimize the performance and reliability of your setup.

FAQs

-

What does AN stand for in AN fittings?

AN stands for “Army Navy” and refers to a standard developed by the military for fluid connections. These fittings have since been adopted by various industries, including automotive and aerospace.

-

What sizes are available for AN fittings?

AN fittings come in a range of sizes, identified by a number. The most common sizes are AN-4, AN-6, AN-8, AN-10, AN-12, AN-16, AN-20, and AN-24. Smaller numbers correspond to smaller fittings, while larger numbers indicate larger fittings.

-

What materials are AN fittings made of?

AN fitting are typically made of aluminum or steel. Aluminum fittings are lightweight and corrosion-resistant, making them suitable for most applications. Steel fittings are stronger and can handle higher pressure, but they are heavier and may require additional protection against corrosion.

4. Do AN fittings require special tools for installation?

Yes, AN fitting require specialized tools for proper installation. These include a bench-mounted vise, a vice jaw adapter, and an AN wrench or spanner. These tools help ensure that the fittings are tightened to the correct torque and prevent damage during installation.

5. Can AN fittings be reused?

AN fitting are designed to be reusable, allowing for easy disassembly and reassembly. However, it is crucial to inspect the fittings thoroughly for any signs of wear, damage, or thread distortion before reusing them. Replacing damaged or worn fittings is essential to maintain a reliable and leak-free plumbing system.

Read More: https://manualwheel.com/choosing-the-per…prehensive-guide/

Read More: https://www.youtube.com/watch?v=IgA_N2ZmTXw