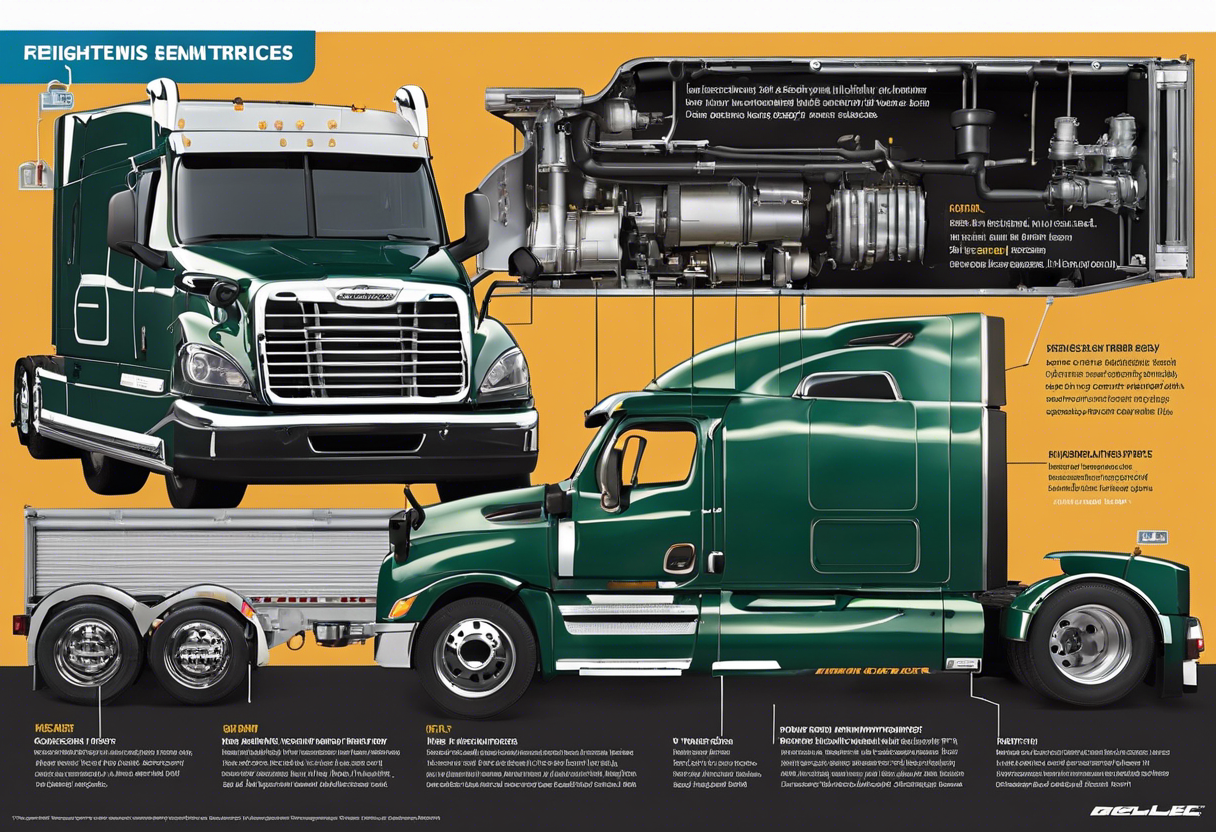

Freightliner Trucks, a division of Daimler Trucks North America, is renowned for manufacturing heavy-duty trucks, often used for commercial purposes. These vehicles are crucial for transporting goods across long distances, demanding reliability and performance in a variety of challenging conditions. The longevity and efficiency of Freightliner Trucks hinge on the use of quality parts. High-quality components ensure safety, minimize the risk of breakdowns, and maintain the vehicle’s operational integrity. Consequently, fleet owners and operators must prioritize regular checks and maintenance using trustworthy parts to safeguard their investment and uphold the rigorous standards that Freightliner Trucks are known for.

The Heart of Your Freightliner:

Selecting the Right Engine Components

When maintaining your Freightliner, it is crucial to focus on the engine, the heart of the truck. Engine components to check regularly include:

-

Air Filters: Essential to prevent contaminants entering the engine, which can reduce efficiency and lifespan.

-

Fuel Filters: Ensure that fuel is clean before it reaches the engine for optimal combustion and performance.

-

Oil Filters: Critical for maintaining oil purity, which reduces wear on moving engine parts.

-

Turbochargers: These boost engine power and efficiency but require careful inspection to avoid failure.

Selecting OEM or reputable aftermarket parts can prevent the costly downtime associated with engine repairs.

Transmission and Drivetrain Upkeep:

Ensuring Smooth Gear Shifts and Power Delivery

Regularly maintaining the transmission and drivetrain of a Freightliner is key to ensuring efficient gear shifts and optimal power delivery. Owners should inspect several components:

-

Transmission Fluid: Check levels and quality regularly, replacing it as advised by manufacturer guidelines.

-

Gearbox: Look for signs of wear or damage, ensuring gears engage smoothly without excessive noise.

-

Drivetrain: Examine driveshafts for integrity, and universal joints for any play or deterioration.

-

Clutch: Assess for wear, particularly in manual transmissions, to prevent slippage or poor engagement.

-

Differential: Inspect for leaks and ensure the lubricant is at the proper level and condition.

Adhering to these tips can significantly reduce the risk of costly breakdowns and maintain the Freightliner’s longevity and reliability.

Braking System Enhancements:

Pads, Rotors, and Calipers for Reliable Stopping Power

Regular inspection and maintenance of a Freightliner’s braking system are essential to ensure the safety and reliability of the vehicle. The brake pads, rotors, and calipers are critical components that require attention:

-

Brake Pads: Check for wear and replace them with high-quality, durable pads to guarantee effective stopping power and prevent damage to the rotors.

-

Rotors: Monitor for signs of warping or excessive wear, and ensure they are properly surfaced to maintain an even and smooth braking surface.

-

Calipers: Inspect calipers for potential leaks or sticking issues, as these can lead to compromised brake performance or even complete brake failure.

These components work together to provide the rigorous stopping force needed for heavy-duty freight transportation, priority safety, and optimal driving performance.

The Role of Suspension Parts in Ride Quality and Freight Protection

The suspension system in a Freightliner plays a pivotal role in ensuring a smooth ride and safeguarding freight during transport. Key components, such as shocks, struts, and springs, absorb and dissipate road irregularities, which helps to prevent damage to the cargo. Consistent performance of the suspension parts is crucial, as it:

- Minimizes the impact of potholes and bumps on the vehicle’s cargo

- Reduces cargo movement and shifting that could lead to freight damage

- Enhances driver control and comfort, contributing to safer driving conditions

- Improves tire contact with the road for optimal traction and braking

Regular checks and maintenance of suspension parts are essential for delivering goods in pristine condition while also providing a comfortable ride for the driver.

Fuel System Maintenance:

Injectors, Pumps, and Filters for Optimal Efficiency

The fuel system is critical for the efficient operation of a Freightliner truck. To maintain peak performance, regular checks on fuel injectors, pumps, and filters are essential. Fuel injectors should be inspected for clogs and damage, as they are responsible for delivering precise amounts of fuel to the engine. The fuel pump, critical for maintaining consistent fuel pressure, requires attention to avoid failure. Lastly, fuel filters should be replaced periodically to prevent contaminants from entering the engine, as debris can severely impair engine performance and fuel efficiency. Monitoring and maintaining these components can prevent costly repairs and downtime.

Cooling System Components:

Radiators, Hoses, and Thermostats to Prevent Overheating

Freightliner trucks depend on a robust cooling system to prevent engine overheating. The key components include:

-

Radiators: They dissipate heat by transferring the thermal energy from the engine coolant to the air.

-

Hoses: These flexible tubes carry coolant between the engine, radiator, and heating system. Regular inspections for leaks and wear are critical.

-

Thermostats: Acting as valves, they regulate coolant flow to maintain optimal engine temperatures. Faulty thermostats can cause overheating or inefficient cooling.

Maintaining these components ensures your Freightliner operates at peak performance, especially under demanding conditions.

Electrical System Essentials:

Alternators, Batteries, and Starters for Uninterrupted Operations

Freightliner vehicles rely on robust electrical systems to operate efficiently. Key components include:

-

Alternators: They charge the battery while the engine runs, powering the electrical system. Regular inspections ensure alternators provide adequate charge and maintain battery health.

-

Batteries: These are the power reserve for starting and electrical needs when the engine is off. Check for clean terminals and replace batteries showing signs of wear or diminished capacity.

-

Starters: Essential for igniting the engine, starters must be reliable. Listen for unusual noises or slow cranking, signaling potential starter issues.

Maintaining these components is vital for uninterrupted freight operations.

Advancements in Exhaust Parts:

DPFs and Mufflers for Emission Control and Noise Reduction

Freightliner trucks have seen significant advances in exhaust components, with Diesel Particulate Filters (DPFs) and high-tech mufflers leading the way. DPFs effectively trap soot and other particulates, drastically cutting down on emissions. Regular checks ensure that DPF regeneration occurs properly, maintaining peak engine performance and adherence to stringent environmental standards.

Mufflers have also been optimized for better noise suppression, utilizing advanced materials and design to minimize sound pollution. This not only contributes to a more comfortable driving experience but also complies with local noise regulations. Both DPFs and mufflers are critical for modern Freightliners, ensuring they meet both emissions and noise control requirements.

Navigational and Safety Upgrades:

Cameras, Sensors, and Monitoring Devices

Freightliner vehicles are often equipped with advanced technologies aimed at enhancing navigation and safety. Operators should prioritize the integrity of these systems. Critical components include:

-

Backup Cameras: Ensure lenses are clear and functional for optimal visibility when reversing.

-

Blind Spot Sensors: Regularly test these sensors to confirm they accurately detect nearby vehicles and obstacles.

-

Lane Departure Warnings: Inspect systems for proper calibration to ensure reliable alerts.

-

Collision Avoidance Systems: Maintain software updates and hardware integrity to support real-time response.

Proper functioning of these devices is vital for safe transportation. Regular checks mitigate the risks of malfunction, which can lead to critical safety issues on the road.

Wrap Up( Conclusion):

When seeking Freightliner parts, prioritize authorized dealers and official distributor channels to ensure authenticity and warranty coverage. For longevity:

- Regularly inspect parts according to the manufacturer’s guidelines.

- Use genuine parts for replacements to guarantee compatibility.

- Adhere to a strict maintenance schedule to prevent untimely wear and tear.

- Employ professional services for installation and repairs to avoid improper handling.

- Store spare parts in appropriate conditions to preserve their quality.

By following these guidelines, you can significantly extend the life of critical Freightliner components.

FAQS about Freightliner Parts

read more: https://www.amazon.com/freightliner-parts/s?k=freightliner+parts

read more: https://manualwheel.com/luxury-on-wheels…cords-collection/