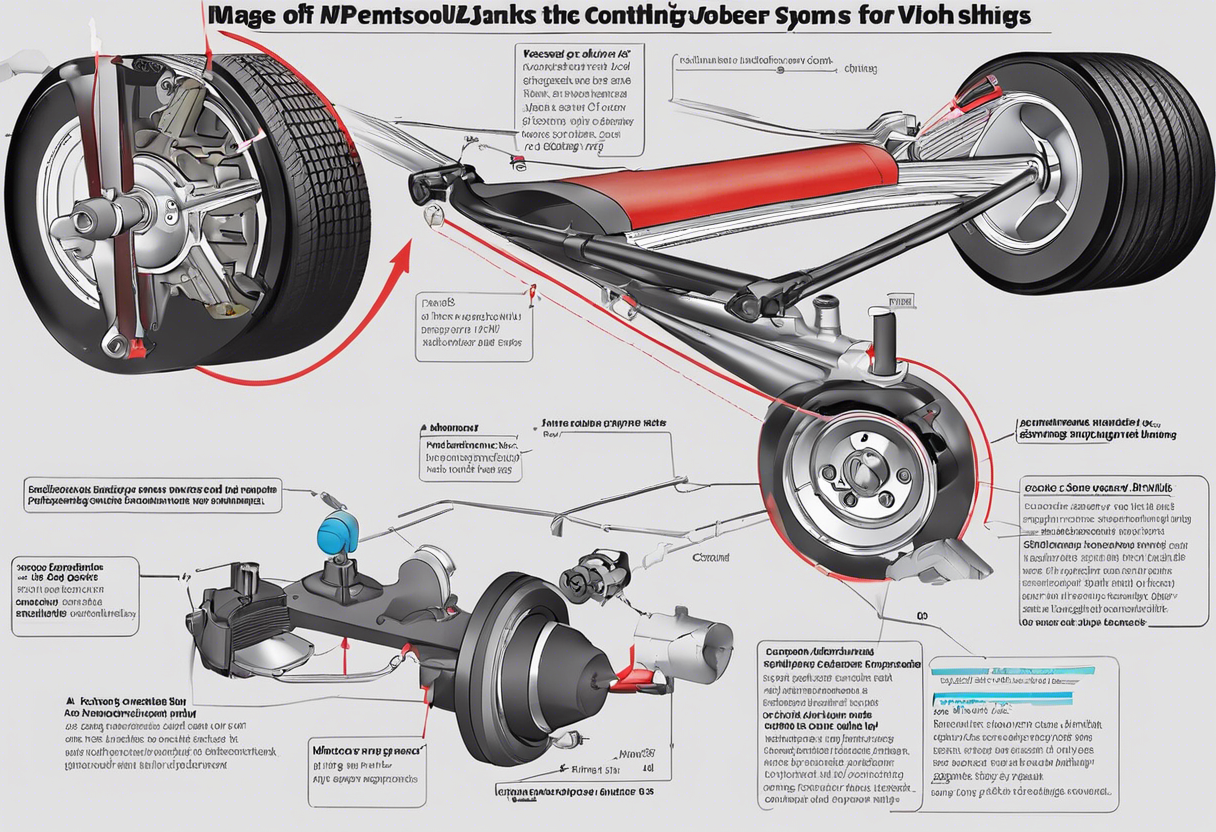

Control arm bushings are pivotal components of a vehicle’s suspension system, serving as the connection between the control arms and the vehicle’s frame. Typically made from rubber or polyurethane, these bushings cushion the vehicle by absorbing road shocks and reducing vibration, thereby ensuring smoother handling. Essential for proper alignment, they allow the control arms to move up and down, maintaining the tires’ firm contact with the road. Properly functioning bushings significantly contribute to overall vehicle performance, influencing ride comfort, handling precision, and tire life. As they deteriorate over time, recognizing symptoms of wear becomes crucial for maintenance.

Key Functions of Control Arm Bushings in Suspension Systems

Control arm bushing serve several critical roles in vehicle suspension systems:

- Absorb Shock: They cushion the car from large bumps and potholes, reducing the amount of vibration transmitted through the chassis.

- Enhance Ride Comfort: By absorbing vibrations, bushings provide a smoother driving experience.

- Improve Handling: They maintain the correct alignment of the wheels, which ensures proper handling and tire wear.

- Reduce Noise: Bushings help to dampen road noise, leading to a quieter cabin.

- Connect Suspension Components: They form a pivot point for the control arms and consequently, maintain the connection between the suspension and the frame.

- Allow for Flexibility: The bushings permit the control arms to move up and down with the road surface while containing excess movement.

Early Warning Signs:

Understanding the Symptoms of Worn Bushings

Recognizing the early warning signs of worn control arm bushing is crucial to vehicle safety and performance. Symptoms include:

- Unusual noises: Listen for clunking or rattling sounds from the wheel wells, especially during turns or over bumps.

- Vibrations: A worn bushing often causes the steering wheel or vehicle to vibrate, which may worsen with acceleration.

- Irregular tire wear: Look out for uneven or rapid wear on your tires; it can indicate that bushings aren’t holding the suspension components firmly.

- Steering issues: Difficulty steering or a wandering sensation can suggest that the bushings are failing and affecting alignment.

- Visual damage: Inspect the bushings for cracking, excessive wear, or deterioration. Physical changes are a clear indicator that the bushings need attention.

Visual Inspection:

Spotting the Physical Signs of Bushing Wear

When inspecting control arm bushing, look for physical indicators of deterioration:

- Cracks or Splits: Examine the rubber or polyurethane of the bushings for visible cracks, splits, or tears, which signal that the material is degrading.

- Excessive Hardening or Softening: Changes in the bushing’s hardness or too much flexibility can indicate it’s failing.

- Corrosion on Metal Parts: Inspect for rust or corrosion on any metal components of the bushing assembly.

- Bushing Distortion: The bushing should retain its original shape; any distortion can be a symptom of wear.

- Uneven Tire Wear: Although an indirect sign, uneven tire wear can sometimes point to a problem with suspension components like bushings.

Auditory Clues:

Identifying Noises Indicating Worn Bushings

When attempting to identify worn control arm bushings, one should listen for specific noises that are telltale signs of deterioration. These include:

- A clunking or knocking sound when driving over bumps or potholes.

- Squeaking or groaning noises that occur during turns or when the suspension is compressed.

- Rattling or thumping sensations emanating from the wheel wells, suggesting bushing material has degraded significantly.

These sounds are often more noticeable during low-speed maneuvers and can be indicative of bushings that require immediate attention.

Tactile Feedback:

How Worn Bushings Affect Driving and Handling

Tactile feedback is the sensation a driver receives through the steering wheel and vehicle seat. Worn control arm bushings degrade this feedback, resulting in a disconnected driving experience. Following are the impacts:

- Steering Precision Loss: Drivers may notice a lack of sharpness in steering response. Worn bushings cannot hold the control arms firmly, leading to play.

- Handling Instability: The vehicle’s handling becomes unpredictable. Wearing bushings fail to maintain proper wheel alignment, affecting stability during maneuvers.

- Vibration Transmission: Increased vibrations and harshness transfer into the cabin. Bushings, designed to absorb road imperfections, lose this ability when deteriorated.

- Noise Development: A clunking or knocking sound often accompanies a compromised bushing, especially over bumps or during cornering.

These symptoms directly hinder driving quality and can lead to safety issues if left unaddressed.

The Impact of Neglected Control Arm Bushings on Vehicle Safety

Neglecting control arm bushings can severely affect vehicle safety. Worn bushings lead to:

- Decreased Steering Precision: As control arm bushings wear out, they become less effective in stabilizing the suspension system, resulting in decreased steering response and accuracy.

- Compromised Wheel Alignment: Deteriorated bushings can cause a vehicle’s wheel alignment to deviate from specifications, leading to uneven tire wear and potential loss of control.

- Increased Braking Distance: Worn bushings may affect the stability of the wheel/tire during braking, potentially increasing stopping distances and increasing the risk of accidents.

- Exacerbated Suspension Wear: Faulty bushings put extra strain on other suspension components, hastening their wear and potentially leading to costly repairs or part replacements.

Ensuring that control arm bushings are in good condition is essential for maintaining the integrity of the vehicle’s suspension, overall stability, and passenger safety.

Diagnostic Approaches:

How Professionals Assess Bushing Condition

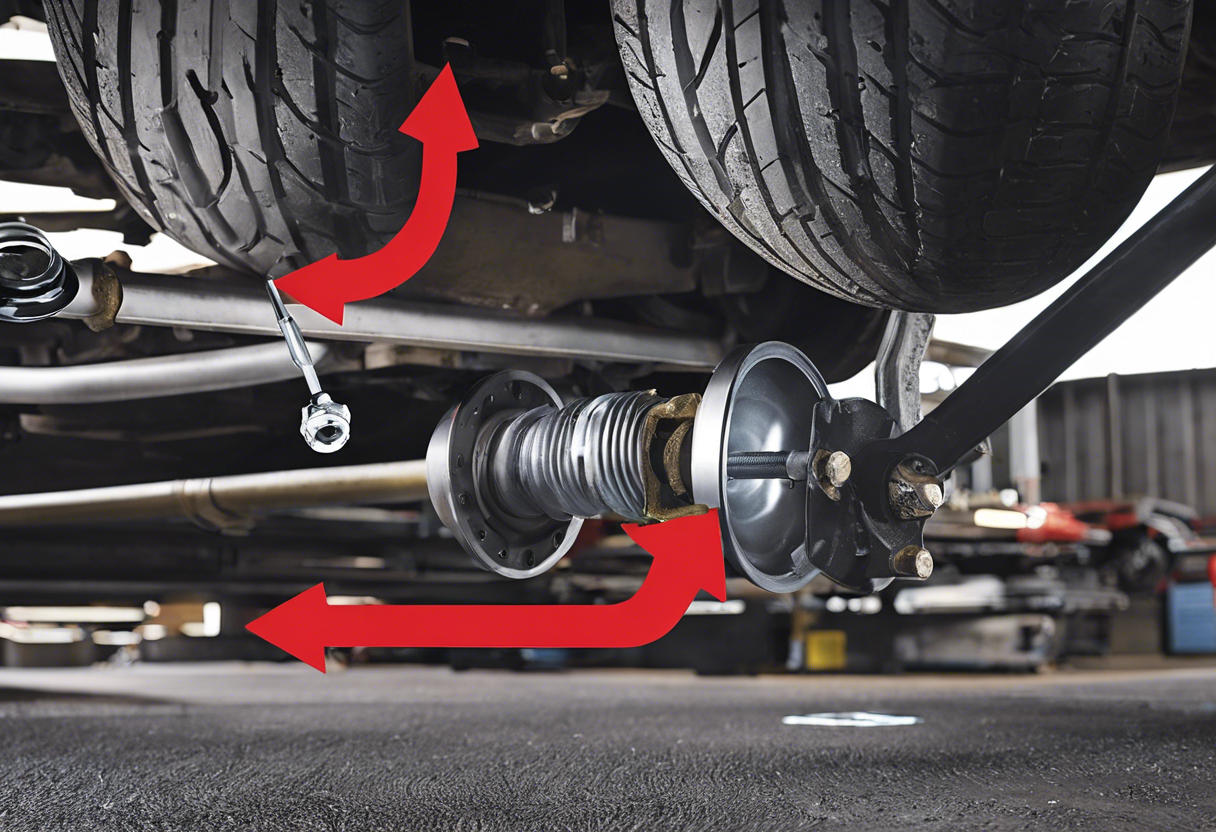

When assessing the condition of control arm bushings, professionals utilize a variety of diagnostic techniques to detect wear and damage:

- Visual Inspection: The most straightforward approach, where mechanics look for signs of physical degradation such as cracks, excessive wear, or contamination by oils and road chemicals.

- Physical Manipulation: Technicians apply force to the control arm to check for excessive movement or unwanted noise in the bushing area indicating possible deterioration.

- Road Test: A driving test to sense vibrations, noises, or handling inconsistencies that emerge due to faulty bushings.

- Lift Test: Lifting the vehicle and using leverage tools to inspect for play or softness in the bushings which could compromise vehicle stability and alignment.

- Measurement Tools: Usage of specialized tools to measure bushing deformation under stress, offering a precise evaluation of their condition.

Through these methods, experts make informed decisions about the longevity and performance of control arm bushings.

Comparing Bushing Materials:

OEM vs. Aftermarket Options

When assessing control arm bushing materials, it’s vital to understand the differences between Original Equipment Manufacturer (OEM) and aftermarket options:

- OEM Bushings:

- Typically made from rubber or high-grade synthetic compounds.

- Engineered to original specifications for an exact fit and function.

- Generally offer a balance between durability and performance.

- More expensive but deliver consistent quality expected by the vehicle manufacturer.

- Aftermarket Bushings:

- Available in a variety of materials, including polyurethane.

- Offer customization opportunities with potential for improved performance.

- May provide enhanced resistance to oil, grease, and extreme temperatures.

- Typically less expensive, but quality can vary significantly across manufacturers.

Preventative Measures:

Tips for Prolonging Bushing Lifespan

To ensure the longevity of your vehicle’s control arm bushings, follow these preventative measures:

- Regular Inspections: Schedule routine check-ups to identify early wear and tear.

- Lubrication Maintenance: Apply suitable grease to bushings if they are not sealed units.

- Drive Carefully: Avoid potholes and aggressive driving that can stress the suspension system.

- Alignment Checks: Ensure proper wheel alignment for even stress distribution on bushings.

- Use Quality Parts: When replacing, opt for high-quality bushings that resist wear better.

- Professional Installation: Ensure bushings are properly fitted to avoid premature failure.

When to Seek Professional Help:

Knowing the Right Time for Replacement

One should consult a professional mechanic if they notice:

- Persistent clunking noises during acceleration or braking

- Excessive vibration or wandering of the steering wheel

- Irregular tire wear indicating misalignment

- The vehicle pulls to one side when driving on a level road

- Difficulty handling or a significant decrease in driving comfort

Early diagnosis and replacement of worn control arm bushings are crucial to maintain vehicle safety and performance. As such, at the sign of any abnormal symptoms, a thorough inspection by a qualified automotive technician is highly recommended.

Conclusion:

The Importance of Timely Bushing Maintenance for Vehicle Integrity

Timely bushing maintenance is not just important—it’s critical for safeguarding the integrity of a vehicle. Ensuring that control arm bushings are in good condition is essential for:

- Preserving tire alignment and prolonging tire life

- Maintaining stability and smoothing the ride for better driving comfort

- Guaranteeing accurate handling and safer maneuvering

- Protecting other vehicle suspension components from excess wear and potential damage

Neglecting bushing maintenance can lead to costly repairs and compromised safety. Thus, vehicle owners and mechanics alike must prioritize the inspection and replacement of worn bushings to ensure the longevity and reliable performance of the vehicle. Regular maintenance is a small investment that pays off in the long-term integrity of your vehicle.

FAQs

- What are the typical symptoms of worn control arm bushings?

- Clunking or knocking noises during acceleration or braking.

- Uneven tire wear.

- Vague or wandering steering feel.

- Can I drive with bad control arm bushing?

- It’s not recommended as it impacts handling and can cause further damage.

- How often should control arm bushing be replaced?

- There’s no set interval; check during regular service or at signs of wear.

- Are control arm bushings expensive to replace?

- Costs vary by vehicle make and model, and whether you need a full arm replacement or just the bushings.

- Can I replace control arm bushing myself?

- Yes, if you have mechanical experience and the right tools, but professional installation is recommended for safety.

for more info: https://manualwheel.com/navigating-the-m…oolant-reservoir/

for more info: https://www.youtube.com/watch?v=Mpz49C1Sv2s